How to improve the operation of an automotive company?

In the article, we answer the following questions:

Would you like to know more about INTENSE Platorm?

Consult our experts for free

Adapt the system and activities to the needs of the automotive industry

It happens that automotive companies operate in several distributed systems. This results in the clutter in the documentation and workflow. Some processes and data from different sources may be difficult to process and integrate. If you want your business to thrive, you should think about:- automation of activities,

- systematization of processes,

- effective organization of work,

- defining the circulation of documents.

Well-chosen software allows you to:

optimize the production process

control surplus stocks of raw materials in warehouses

improvement of urgent work

monitor the work of the team

effectively define and change delivery dates

record materials

Management of stock and raw materials

Automotive component manufacturing companies often choose to order raw materials in advance. In this industry, it is worth spending time on precise planning of the production process. This can lead to cost optimization, teamwork, and a positive impact on customer feedback. Warehouse management is also an important issue. The management system allows you to control stock levels, manage orders, automate the generation and shipping of documents, and additionally, it enables work planning and process control.

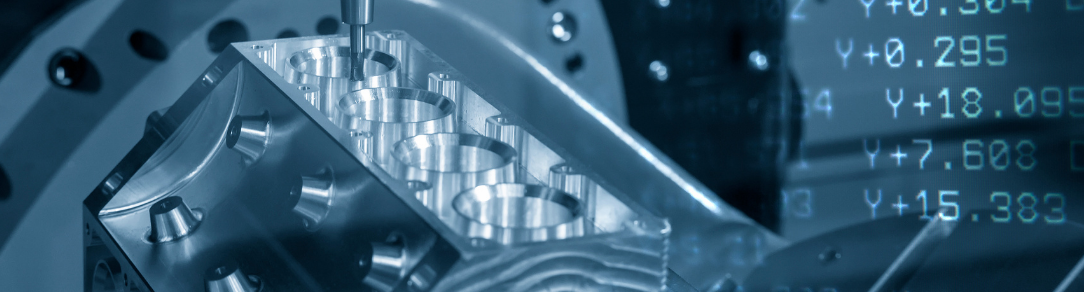

Optimization of production work

Planning production work in a large company is a huge challenge. You can use dedicated software to automate many processes and monitor your team’s activities. Establishing a workflow allows you to optimize activities, plan holidays and effectively deal with employee absences, interruptions, etc. IT systems for production management come to the aid of the challenges in production optimization. The implemented system will contain precise data on the available raw materials, as well as a package of precise information on what orders, on what materials will be made in the production hall. The production manager has comprehensive information on various orders based on which he can precisely forecast the production and use of the company’s equipment. In addition, a properly designed production management system will automatically show the breakdown of costs for individual orders on a given day, week, or month.Collect and analyze data

Precisely created and legible reports allow for a quick response to current revenues in the company, problems, or sales drops. Advanced systems allow you to create plans, monitor their implementation, set up automatic notifications in the event of drops, and carry out many other activities that will improve the efficiency of your team. By implementing the system, you can monitor companies on an ongoing basis and use up-to-date information. Reports can be generated automatically. By integrating data with multiple sources, you can control multiple parameters and compare them. You can be sure that the statements will be legible, correctly described, and automatically generated in the time intervals you choose.

Flexible solutions are the key to success

Close cooperation with contractors and the highly automated processes they use require a smooth and lossless flow of information, also between enterprises and software platforms. Business processes that are ideally suited to the needs of customers determine success in the industry. It is also worth paying attention to when choosing a system to manage your automotive company. A personalized solution that can be tailored to your needs and customer requirements.The flexible solution enables, among other things:

automation of notifications and actions

monitoring information and implementation progress

determining the accesses according to the needs

improvement of legalistic activities

modification of processes and schemes

mobile activity

creating reports and analyzes as needed

establishing any processes

The key to the success of companies specializing in the production and distribution of automotive parts and accessories is the use of tailored solutions for the automotive industry. System solutions, implemented by i-systems, such as optimization of order management or project management system, automate many processes taking place in the company.